Moreover, the machine’s design encourages easy maintenance and repair, which is vital for continuous operation in busy factories. The simplicity of its components allows for quick troubleshooting and replacement, minimizing downtime. As businesses seek to optimize their production lines, the reliability of the modern chain stitch machine plays a crucial role in sustaining operations and maximizing output.

- One of the main benefits of a heavy-duty handheld sewing machine for canvas is its portability. Traditional sewing machines can be bulky and difficult to transport, but a handheld machine can easily be taken on the go. This makes it perfect for anyone who needs to do sewing projects in different locations or on the go.

What Are The Top Five Questions To Consider Before Buying Your Next Heavy-Duty Sewing Machine?

To effectively use a manual leather stitching machine, artisans must grasp a few key techniques. First, the selection of the right thread and needle is crucial. Leather thread, typically made from synthetic materials or waxed cotton, is preferred for its strength and durability. The needle should be specific to leather, with a sharp point that can penetrate the tough material without causing excessive damage.

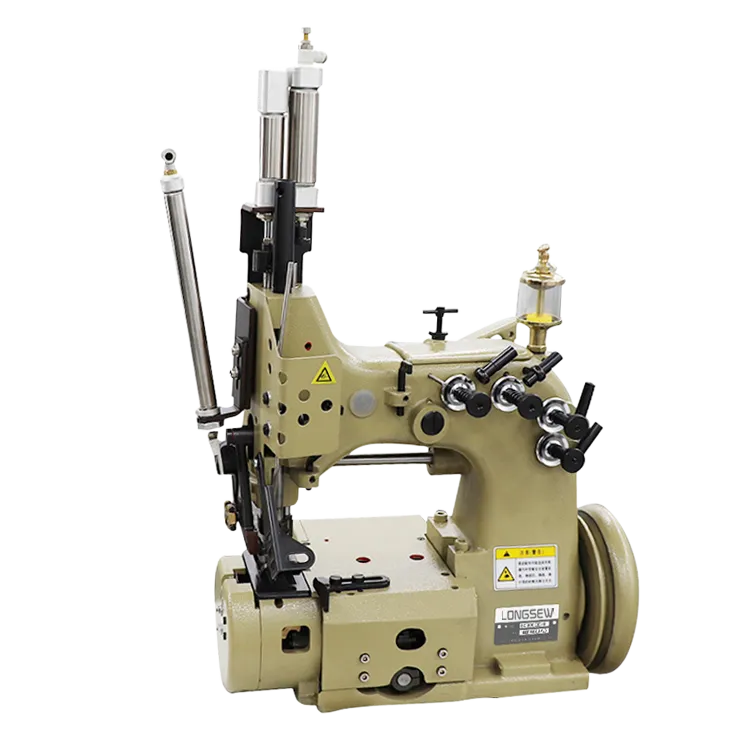

manual leather stitching machine

Zigzag stitching is a fundamental feature in modern sewing machines, allowing for versatility in sewing techniques. The zigzag stitch not only provides a decorative finish but also enhances the functionality of sewn seams. It is particularly useful in preventing fraying and offering stretch, making it ideal for knit fabrics and stretch garments. High arm zigzag sewing machines combine this essential stitching capability with the benefits of ample workspace and adjustable settings, allowing users to create high-quality projects with ease.

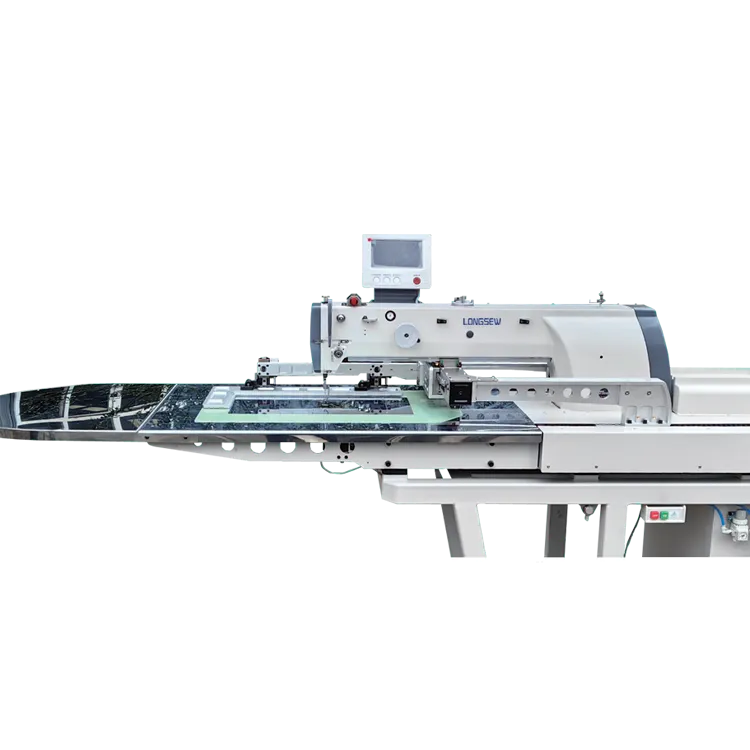

long arm & high arm zigzag sewing machine

Conclusion

1. Thread Choice The type of thread used can affect both the look and durability of your quilt. Opt for high-quality cotton threads for most projects, but consider experimenting with specialty threads for unique effects.

For those considering adding a zig zag stitch machine to their sewing toolkit, it’s important to recognize the range of options available on the market. Modern machines often come equipped with a myriad of additional features, such as automatic threading, a variety of stitch patterns, and built-in tutorials. These advancements make it easier for both beginners and experienced seamstresses to harness the potential of the zig zag stitch.

Versatility in Applications

2. Walking Foot A walking foot can help prevent layers of leather or vinyl from shifting as you sew, resulting in straight seams and a professional finish. This feature is particularly beneficial for users working on projects that involve multiple layers.

A compound feed sewing machine is distinct due to its ability to feed the material from multiple sources—primarily the needle and the feed dog. This dual feeding mechanism helps to maintain an even tension on the fabric, ensuring that layers of varying thickness can be sewn together without puckering or shifting. The combination of the needle feed, presser foot, and feed dog working in unison allows for precise control over the sewing process, enabling seamless stitching even on difficult materials.

What is a Handheld Leather Stitcher?

If you encounter issues with fabric feeding unevenly or getting stuck under the presser foot, check that the feed dogs are clean and free from debris. Use a brush or vacuum attachment to remove any lint or thread buildup from the feed dogs and ensure that they are moving smoothly.

2. Enhanced Aesthetic Appeal Thick threads add a visual element to leather projects. The pronounced stitches create a statement on the surface of the leather, enhancing the overall design. Contrast stitching, where the thread color differs from the leather, becomes especially pronounced when using thick thread, allowing artisans to experiment with colors and design patterns that elevate the aesthetic value of their creations.

thick thread for sewing leather

In the realm of sewing and garment construction, various techniques and stitches play an integral role in determining the durability and aesthetic quality of a finished product. Among these, the overlock chain stitch stands out for its unique application and functionality. This article delves into the characteristics, benefits, and applications of the overlock chain stitch, providing insights for both novice and seasoned seamstresses.

At the core of the double needle chain stitch sewing machine lies its unique threading system. Unlike conventional sewing machines that use a single needle and bobbin mechanism, the double needle machine operates with two needles threaded simultaneously. These needles penetrate the fabric and form a chain stitch, which is a type of stitch characterized by its interlocking loops. The two needles work in tandem to create parallel rows of stitching, resulting in a strong seam that can withstand stress and strain.

Key Features to Look For

2. Use the Correct Thread Pairing the right thread with long upholstery needles is essential. Heavy-duty threads, such as polyester or nylon, work best for upholstery projects, ensuring durability and strength in the seams.

3. Protection Against Contamination Providing a secure seal helps protect the contents of the bags from external contaminants, which is essential in industries dealing with food products, chemicals, or other sensitive materials. An effective lock stitch seam minimizes the risk of spillage and contamination during transit.

The Role of the Puller Mechanism

Coverstitch chain stitching is predominantly used in the finishing process of hems, especially on knit fabrics. It is commonly found on t-shirts, leggings, jerseys, and activewear due to its ability to stretch and recover. However, its applications go beyond hems. The coverstitch can also be used for attaching bindings, reinforcing seams, or as a decorative feature on the surface of garments, making it a multifaceted addition to any sewing toolkit.

In today’s textile and garment industry, efficiency and quality are paramount. For businesses that demand precision and versatility in their sewing operations, investing in an industrial long arm sewing machine can make a significant difference. This article explores the benefits of these machines, their applications, and what to consider when purchasing one.

Furthermore, sewing machines with built-in walking feet often come with additional advanced features that enhance the overall sewing experience. These can include adjustable stitch widths and lengths, automatic needle positioning, and even computerized stitch selection, which can elevate any sewing project. Such enhancements cater to both beginner and experienced sewists, allowing users to develop their skills and take their sewing to new heights.

3. Durability and Build Quality The materials and construction of the machine can also affect its price. Professional-grade machines constructed with metal components are often more expensive but are built to withstand high-volume use in a commercial setting.

The Evolution and Impact of Sewing Machine Chains

Applications of Heavy Duty Sewing Needles

1. Finishing Edges

Understanding the Industrial Chain Stitch Machine A Key Player in Textile Manufacturing

4. Maintenance and Support Regular maintenance is crucial for overlocker longevity. Look for machines that are easy to maintain and have accessible customer support or local service centers.

3. User-friendly Interface Many programmable sewing machines are designed with user-friendly interfaces that include touch screens, making it easy to navigate through menus, select patterns, and adjust settings. This intuitive design helps reduce the learning curve, allowing new users to quickly become proficient in their machine’s features.

programmable pattern sewing machine

Understanding the Manual Leather Sewing Machine

Current PP bag stitching machines come with various features designed to improve performance and user experience. These machines typically incorporate automated feeding systems that ensure a consistent flow of bags, reducing downtime and labor costs. Additionally, many models have adjustable stitch patterns, allowing manufacturers to modify the closing technique depending on the bag's intended use.

In conclusion, the double needle is a powerful tool in the arsenal of any serious sewist. It combines practicality with artistry, allowing users to create beautiful, professional-quality finishes that are both functional and stylish. Whether you are a seasoned professional or a passionate hobbyist, incorporating a double needle into your sewing repertoire can open up a world of creative possibilities. As sewing continues to evolve with trends in fashion and technology, the double needle remains a timeless tool, empowering sewists to bring their visions to life with precision and flair.

jumbo bag lock stitch sewing. Additionally, the lock stitch seam is less likely to unravel over time, ensuring the bag remains intact and reliable for multiple uses.

What if you need a machine that is more industrial but you don’t have the space or the budget for a true industrial machine?

Handheld sewing machines are generally not as durable as heavy-duty sewing machines. They may not withstand frequent use or handle larger sewing projects as well. If you're looking for a long-term investment, you might want to consider other options.

Conclusion